If you are an industry leader in clinical or commercial enterprises, such as biotech, pharmaceuticals, and cell and gene therapy, then you understand how important the commissioning process is. Commissioning services provide your business with a comprehensive approach to the validation and optimization of production and manufacturing processes. This blog post will provide an overview of what commissioning services are and why they are essential for any successful biotech operation.

Our team at Bothwell Engineering Inc. are experts in biotech commissioning services, offering everything you need to successfully validate your mission. We tailor our programs to the specific needs of our clients with commissioning, and validation plans that employ the latest industry standards. Startup services run the gamut from cycle development to commissioning, equipment cleaning, and computer systems validation. Now, without further ado, let’s get into the minutiae of commissioning services.

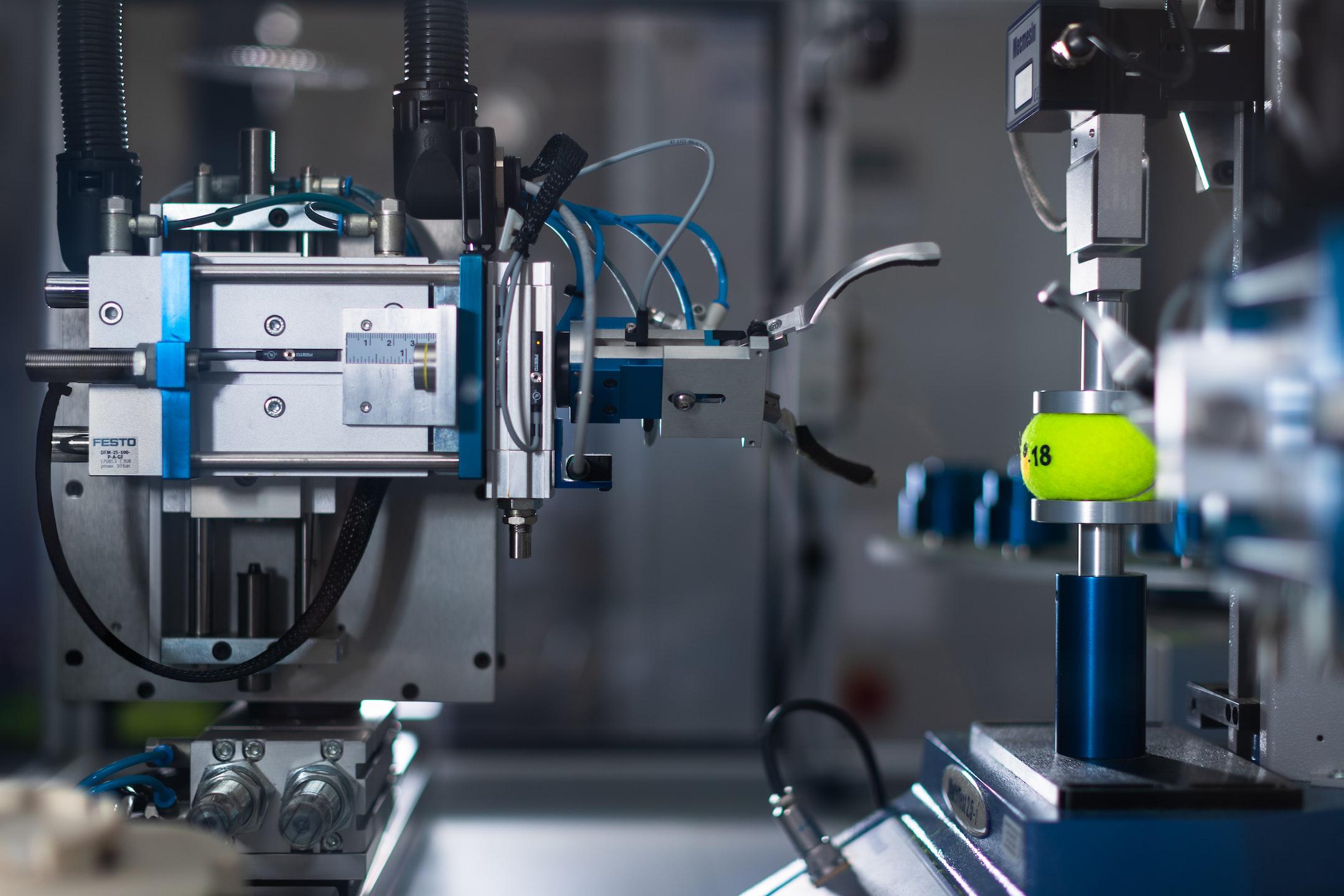

Commissioning is the process of verifying that all equipment, systems, and processes are performing as intended in order to ensure successful operation. It is an essential part of any biotech manufacturing process, as it ensures that all systems are operating correctly before product delivery. This includes testing both hardware and software components to make sure they are functioning properly.

The commissioning process typically starts with a review of the design documentation and specifications for each system or component. During this review, any discrepancies between the design documentation and actual installation will be identified and addressed. Once this review is complete, a test plan is created which outlines all tests that need to be performed on the system or component prior to commissioning. These tests typically include temperature readings, pressure checks, flow measurements, leak tests, electrical measurements, vibration analysis, noise testing, etc., depending on the specific requirements for each system or component being tested.

Once all tests have been completed successfully, then the system or component can be commissioned for use in clinical trials or commercial production runs. Commissioning provides confidence in both performance and quality assurance standards throughout the entire life cycle of a product—from development through production release—ensuring that products perform according to specified criteria before being released into general use. Finally, commissioning also provides analytical data which can then be used to optimize performance during operations and maintenance activities throughout the life cycle of any product manufactured using biotechnological processes.

As a business leader in clinical or commercial enterprises within biotech industries, you understand how important it is to have reliable systems in place. By utilizing commissioning services from experienced professionals like those at Bothwell Engineering Inc., you can rest assured that your systems will be up-and-running in no time. With our expertise in pharmaceutical manufacturing processes engineering, we can help you make sure that every step of your production process is correctly optimized for maximum efficiency and reliability. This includes everything from designing new systems to certifying existing ones—all with minimal downtime and disruption to your workflow.

Commissioning services from experienced professionals like those at Bothwell Engineering Inc., can help ensure that your clinical or commercial enterprise runs smoothly without interruption or disruption due to system malfunctions or other problems associated with improper installation processes. Our team of experts provides comprehensive commissioning services tailored to each customer’s unique needs; from detailed inspections and testing down to creating detailed reports outlining our findings so customers have total transparency on what has been done during a given commission job—from start to finish! Contact us today for more information on how we can help optimize your production process today!