Manufacturing is a critical part of getting new pharmaceutical and biotech products out to everyone from retail customers to large-scale clients like healthcare organizations. It’s a process that’s made up of several units, like formulation, powder feeding and blending, milling, granulation, and hot melt extrusion. All of these require the use of manufacturing equipment that meet industry-standard guidelines and make the process as efficient as possible.

When you’re in need of a new piece of manufacturing equipment to make this process possible, there are some critically-important details you need to take into account. You need to be sure that the tool you’re looking for has a clear purpose to serve in your process and to understand that purpose thoroughly, and that every tool you use is going to perform its role effectively without posing a safety risk to your employees or consumers.

Staying on top of these details may be easier said than done, however. What exactly should you be thinking about when considering the role a new piece of equipment is going to play in your process? What kinds of safety concerns should you particularly be aware of, and what’s the best way to go about mitigating any risks your equipment may pose? We’ll cover these questions and more in this blog post.

As mentioned previously, there are multiple phases of the product manufacturing process that require the use of unique tools. For any number of reasons, you may find yourself needing new equipment for any of these units; new safety issues may have cropped up with a particular piece of equipment, or it may have simply become a liability in the face of new, improved models of the same tool that can improve your operational efficiency.

Before installing a new piece of equipment, the primary detail you should be thinking about is the role that tool is going to play in your process. If you’re replacing a tool you already had, how does this new piece of equipment make up for the shortcomings of the old one? What exact benefit are you expecting to your process and end products from employing this new tool? Is a particular tool you’re considering the best replacement available given the needs of your business?

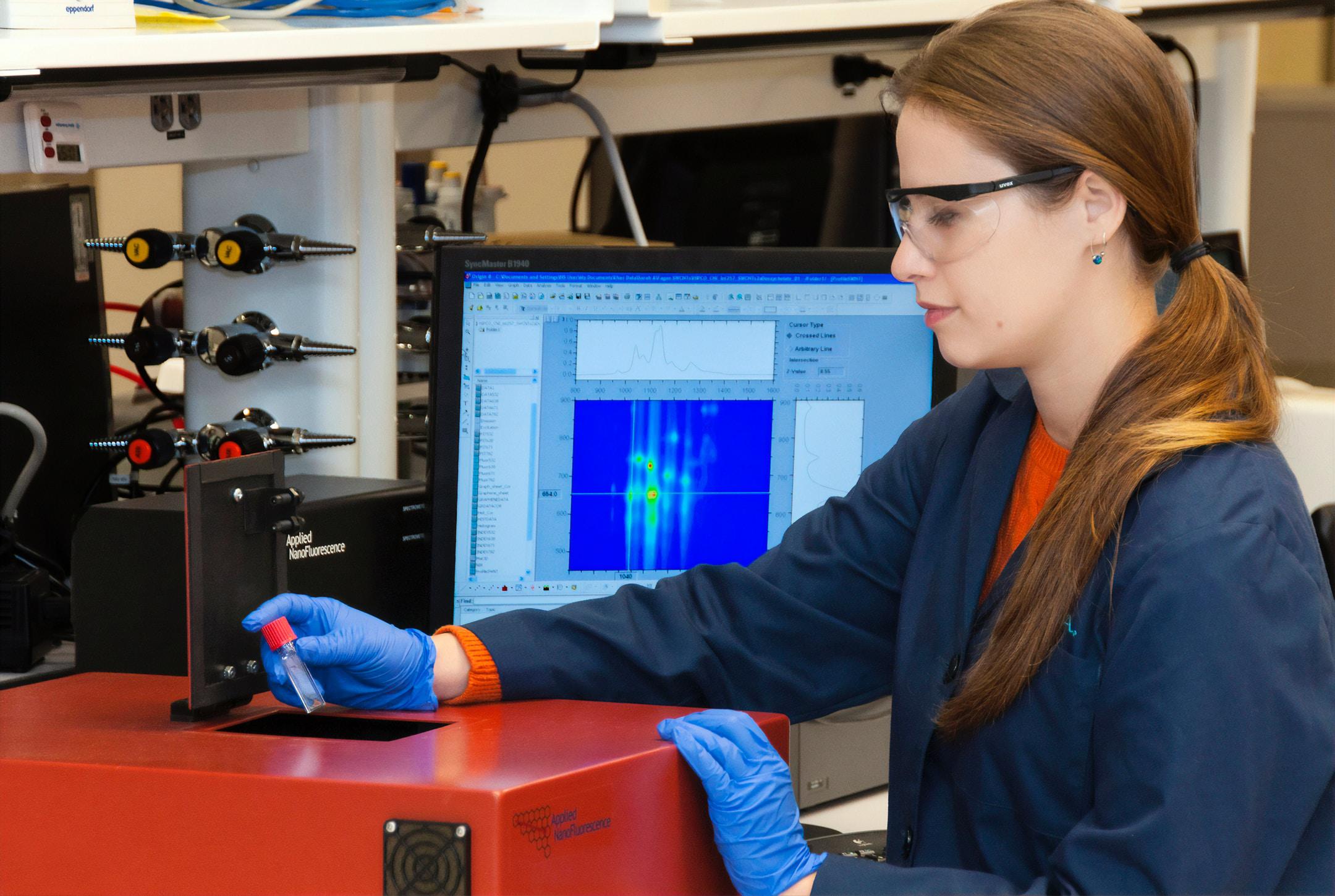

Safety considerations are an even more important detail to take into account than any benefits you can expect out of using a given tool. When manufacturing pharmaceutical and biotech products, your employees could be exposed to any number of potential hazards. These, of course, include some risks posed by the tools themselves, such as moving pieces, the need to move heavy equipment manually, heat, pressurization, and more.

The products themselves may also pose a danger to both your team and consumers. During the manufacturing process, hazardous chemicals could come into contact with employees, leading to traumatic injury and chronic health conditions, particularly if these chemicals come into contact with hair, skin, or eyes. Failures in the manufacturing process could also pass on adverse effects to the final product, leading to health risks for users of these products.

The equipment you use to create your products has a tremendous effect on the well-being of your team, your customers and clients, and ultimately, your business. Do you need help assessing whether a new equipment installation is needed or potentially beneficial for manufacturing your products? The experts at Bothwell Engineering are ready to work with you. Get in touch with us now for more information about how we can help.